Compressor Performance Curves Pdf

By Hank van Ormer, Contributing Editorexplained necessary terminology to understand centrifugal operations. Part II reviews typical operating performance curves and how to interpret them.A centrifugal air compressor operates over a range of flows and discharge pressures. The operating performance curve is shaped by the selected individual internal components and affected by operating conditions such as inlet pressure, inlet temperature, and cooling water temperature.The process of dynamic compression, as applied in a centrifugal compressor operating stage, is velocity and kinetic energy converted to pressure and temperature as the flow is restricted. Another term for this process is mass flow – the power requirement to deliver the rated cfm of flow at the rated pressure (psig) is determined by the weight of the air (some manufacturers also use the term “density”).The power requirement in this type of compression process, when the internal design parts are not considered, is basically dependent on the weight of the air going through the machine. Ignoring part loads controls anything that will increase or decrease the weight of the air going through the stages to final flow, and pressure will have a direct impact on input power.Figure 1a.

Effect of inlet air temp on discharge pressureFigure 1b. Effect of inlet air temp on powerIncreasing the inlet temperature will lighten the total fixed air flow and deliver less usable air to the user (scfm) and reduce the input power requirement. Colder temperatures will produce the opposite effect.Reducing the inlet pressure (altitude, negative compressor room pressure, dirty/poorly sized inlet filter) will lighten the compressed air flow (cfm) that travels through the stages also resulting in less usable air (scfm) at a reduce input power requirement. Higher inlet pressure will have the opposite effect.Increasing the cooling water temperatures will again have the same “lightening” effect on the compressed air through the stages and power requirements as the previous conditions.The actual net effect of any of these conditions is dependent on the actual performance curve and aerodynamic characteristics of the design. This is also the case of discharge pressure with a fixed wheel, or impeller/diffuser/speed, compressor stage.Increasing the discharge pressure will normally leave the effect of raising the weight of the compressed air stream through the stages which will result in less flow of usable air (scfm) often at or near the same input power.

Lowering the pressure will often allow more flow at the same or similar power input. Actual machine specific performance is covered later in this document.Understanding Centrifugal Manufacturer Operating CurvesData should be equalized to:. SCFM or Nm 3/hr at full and part loads.

Input power at kW. Pressures either in psig or bar (only using psia to convert from icfm/acfm to scfm)Figure 2.

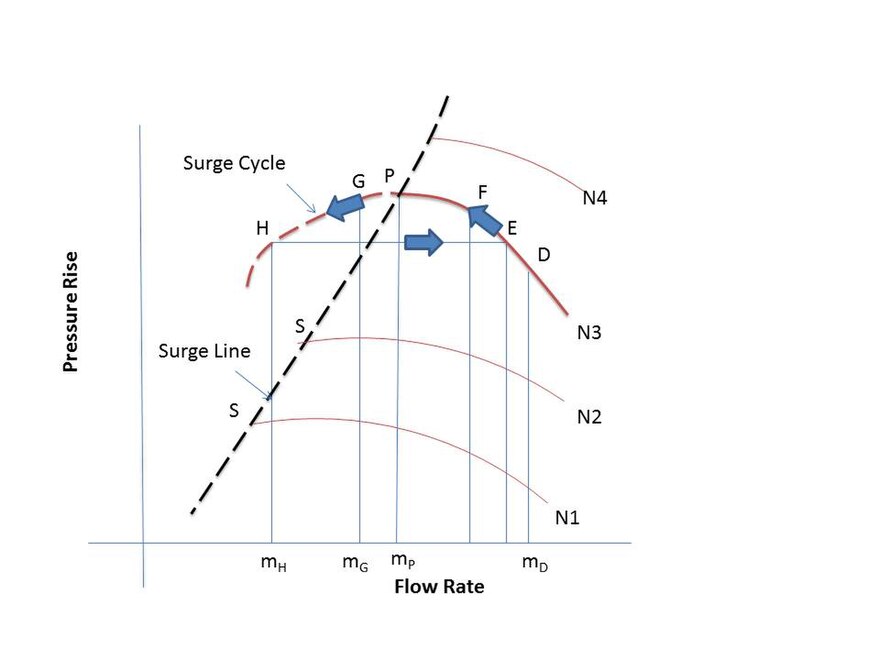

Typical centrifugal performance curvesWhat are Turndown, Stonewall, and Rise to Surge?Once an impeller is designed and a speed set, the energy that a pound of air will absorb in passing through the impeller is established.A centrifugal compressor will deliver a pound of air with a constant expenditure of energy - winter or summer. The actual volume of inlet air to be compressed will vary for a period of time with the inlet condition of pressure and temperature.Rise to Surge: As more compressed air is produced than needed, the centrifugal compressor must unload, or deliver less air to avoid over pressure.

Florida point suspension. To maintain all of your driving privileges in the state of Florida, it's important that you understand how the point system works so you can maintain a clean driving record.The FL Department of Highway Safety and Motor Vehicles is responsible for keeping track of point violations on your Florida driving record. How the FL Point System WorksIn Florida, many of the common traffic infractions are given a number value, recorded as “points.'

Compressor Performance Curves Pdf Free

Each centrifugal compressor has a maximum pressure it can reach for specific inlet conditions which will cause the air flow to reverse and surge, shutting off the compressor to avoid damage from the vibrations.This is an oversimplification of the surge action, however, each unit has a rise to surge limit or maximum pressure. Turndown is the percentage below full load flow the compressor can run without experiencing surge. For example, 15% turndown means the unit can run at 85% flow or higher, as equipped without hitting surge.

At greater turndown, it will be close to or at surge.Stonewall: At some point, as the discharge falls and the air flow through the increases at full load, the physical limitations will not allow more air through the stages – this point is known as stonewall. Continued operation at or beyond this point can cause such high flow rates with greater pressure differential that the impellers will not totally fill the vane areas and a cavitation-like action will occur creating another type of surge with potentially damaging vibrations.Figure 3 is a sample representation of a general manufacturer’s performance curve and the data can be developed to a predictable and probable actual projected operating efficiency.Figure 3. Sample performance curves for full load compressor at 125 psig. 2,050 cfm at 125 psig at 430 HP (x.7457 = 321 kW). Turndown 1,535 cfm at 125 psig at 345 HP (x.7457 = 257 kW)Utilizing the Centrifugal Operating Performance Curves for System OptimizationWorking with an OEM supplier and their operating performance curves effectively will help to lead to a successful application.